| Standard: | ASTM A240, ASME SA240 | Material Grade: | TP304, UNS S30400, 1.4301 |

|---|---|---|---|

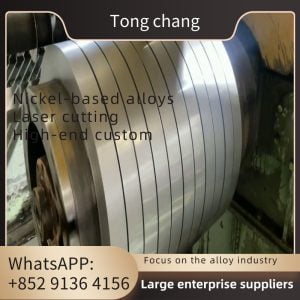

| Type: | Coil, Strip | Length: | As Customer’s Requests |

| Technique: | Hot, Cold Rolled | Application: | Construction,Industry,Decoration,Automotive,Etc. |

| High Light: | 1.4301 Stainless Steel Coils, TP304 Stainless Steel Coils, Construction Precision Steel Strip | ||

ASTM A240 TP304, UNS S30400, 1.4301 Stainless Steel Coils, Strips For Chemical Industry

TP304 (UNS S30400, 1.4301) stainless steel is widely used to make equipments and machine parts that require good comprehensive performance. In order to maintain the inherent corrosion resistance of stainless steel, the steel must contain more than 18% chromium and more than 8% nickel content.The property of resistance to corrosion offered by TP304 against the medium-level strong organic acids is functional due to their nickel content. While the resistance to corrosion caused by oxidizing atmospheres is combated with the help of the chromium levels in the TP304 stainless steel.

| Standard | ASTM A240 / ASME SA240 |

| Thickness | 0.2mm – 5.0mm |

| Width | 3.2mm – 1500mm |

| Length | As Per Customer’s Requirement |

| Coils Hardness | Half Hard, Quarter Hard, Soft, Hard, Spring Hard |

| Finish | Hot rolled Coils (HR), Cold rolled Coils (CR), NO.1, 2B, 2D, 2H, 2R, No.4, HAIRLINE, SCOTCH BRITE, SATIN FINISH, NO.8, BA. |

| Form | Coils |

Equivalent Grades:

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

| BS | En | No | Name | ||||

| TP304 | S30400 | 304S31 | 58E | 1.4301 | X5CrNi18-10 | 2332 | SUS 304 |

Features:

Great toughness

Formability and welding properties

Great hardening by cold working

Ease of cleaning

Deep drawing quality

Ease of fabrication

Good strength and toughness at cryogenic temperatures

Chemical Composition:

| C | Mn | Si | P | S | Cr | Ni |

| 0.08 max | 2 max | 0.75 max | 0.045 max | 0.03 max | 18 – 20 | 8 – 11 |

Mechanical Properties:

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35-40 % |

Applications:

Oil & Gas Industry

Chemical Industry

Construction Industry

Offshore Pipelines

Petrochemical Industry

Shipbuilding Industry

Hydraulic Applications

Piping Systems

Architecture & Construction