| Type: | SEAMLESS / ERW / WELDED/ FABRICATED | End: | Plain End, Bevelled End, Threaded |

|---|---|---|---|

| Inspection: | ET, HT, UT , PMI | Name: | NICKEL ALLOY STEEL 8020 SMLS PIPE |

| High Light: | UNS N08020 Nickel Alloy Pipe, ASTM B729 UNS N08020, ISO Approved Nickel Alloy Pipe | ||

ASTM B729 UNS N08020 Alloy 20 2.4660 Nickel Alloy Steel Annealed and Pickled. BE. PE.

ASTM B729 UNS N08020 Alloy 20 2.4660 Nickel Alloy Steel is a specific type of pipe made from Alloy 20 (also known as Carpenter 20) – a nickel-iron-chromium alloy with excellent resistance to corrosion, particularly in sulfuric acid environments. Here are some key features and advantages of this:

Advantage:

1️⃣ Corrosion Resistance: Alloy 20 are highly resistant to various corrosive media, including sulfuric acid, phosphoric acid, nitric acid, and chloride-containing environments. This makes them suitable for applications in chemical processing, pharmaceutical, food processing, and petrochemical industries.

2️⃣ Versatility: The alloy's resistance to corrosion makes it well-suited for a wide range of applications, including pipe fittings, heat exchangers, valves, pumps, and tanks. It can handle both hot and cold solutions and is often used in environments where other materials may fail.

3️⃣ High Strength: Alloy 20 offer good mechanical strength and excellent toughness, enabling them to withstand high-pressure and high-temperature applications. They have a good combination of strength, formability, and weldability, making them versatile for various fabrication processes.

4️⃣ Stability and Durability: have a uniform structure without welds or seams, enhancing their structural stability and resistance to leakage. They also have enhanced durability compared to pipes with welded joints, reducing the risk of failures.

5️⃣ Ease of Installation: ASTM B729 UNS N08020 Alloy 20 come in standardized sizes and lengths, simplifying installation and compatibility with existing systems. They can be easily joined with other piping components using common methods such as welding or flanging.

| Thickness | 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

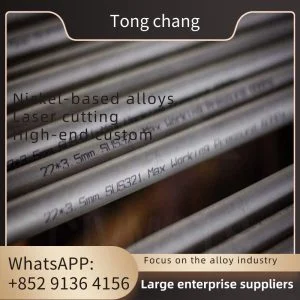

| Outer Diameter | 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB |

| Type | Seamless / ERW / Welded / Fabricated / CDW |

| Form | Round Tubes, Square Tubes, Rectangular Tubes, Coiled Tubes, “U” Shape, Pan Cake Coils, Hydraulic Tubes |

| Length | Single Random, Double Random & Required Length |

| End | Plain End, Beveled End, Treaded. |

Sizes of ASTM B729 Alloy 20 Tubes

- Alloy 2.4660 ERW Tubes : 1/2″ NB – 24″ NB

- UNS N08020 : 1/2″ NB – 16″ NB

- Alloy UNS N08020 EFW Pipe : 6″ NB – 100″ NB

- Carpenter 20 Tubes : 1/8″NB TO 30″NB IN

Chemical Equation of 20 Alloy Welded Tube

| Alloy 20 | Ni | C | Mo | Mn | Si | Fe | Cu | S | P | Cr |

| 32 – 38 | 0.02 max | 2 – 3 | 1 – 2 | 0.7 max | Bal | 3 – 4 | 0.005 max | 0.02 max | 19 – 21 |

Mechanical Behaviour of ASME SB729 Alloy 20 Tubing

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 8.1 g/cm3 | 1443 °C (2430 °F) | Psi – 35000 , MPa – 241 | Psi – 80000 , MPa – 551 | 30 % |

Equivalent of Carpenter 20 Electropolish Tube

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | BS | GOST |

| Alloy 20 | N08020 | 2.4660 | Z2NCUD31-20AZ | NiCr20CuMo | – | – | – |